Zone Cabling for Cost Savings: Plenum Environments

Workspaces are becoming increasingly social and flexible and are constantly being re-arranged and updated. To determine how structured cabling can best support this evolving trend, Siemon studied the cost and environmental impact of various structured cabling designs used in plenum spaces. The results are in: zone cabling deployments provide the optimum balance of performance, flexibility, and efficient use of cabling materials in today’s enterprise environments.

What is Zone Cabling?

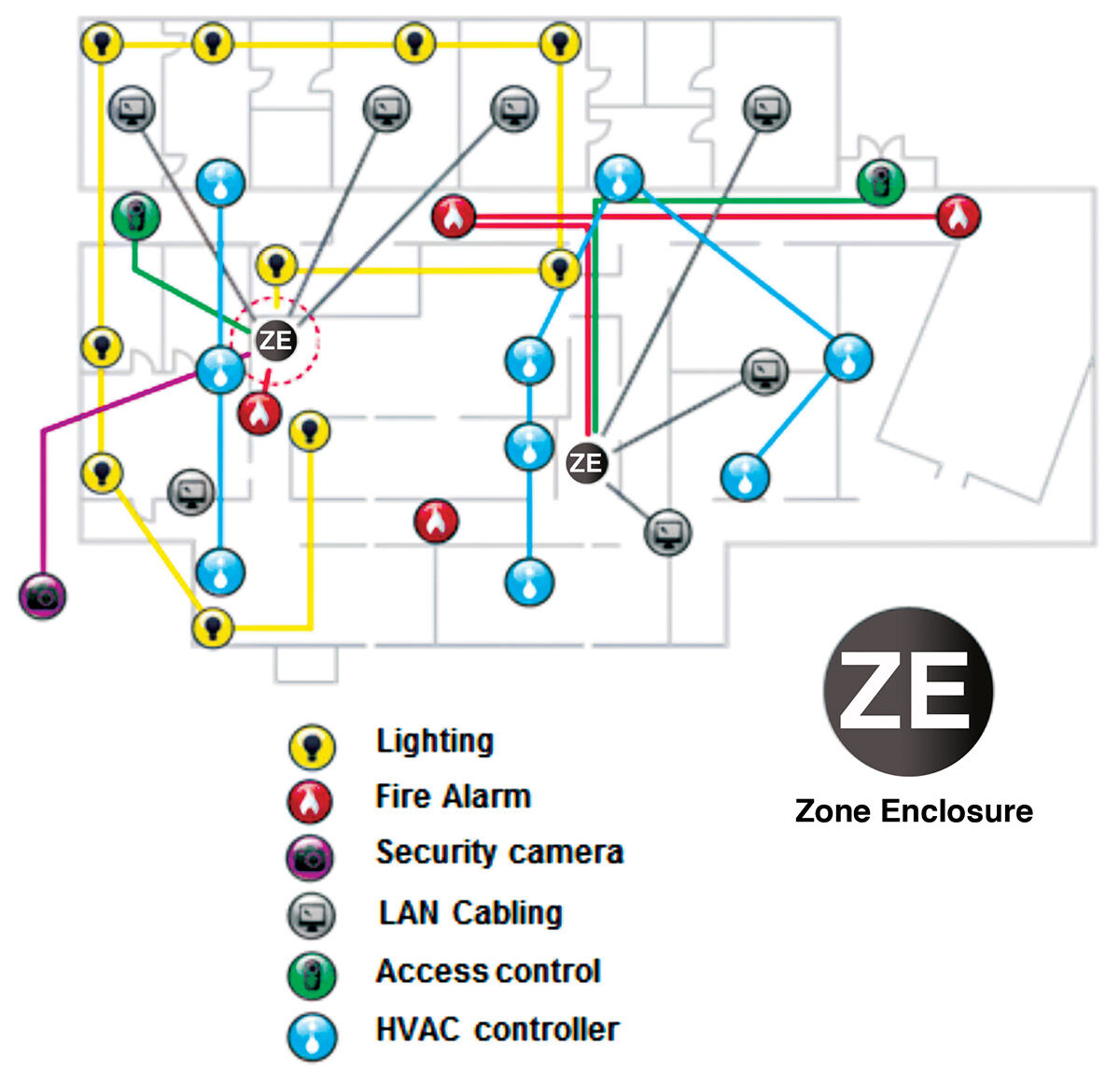

A zone cabling design (or topology) begins with horizontal cables run from patch panels in the telecommunications room (TR) to connections within a zone enclosure (ZE, sometimes referred to as a zone box), which can be mounted under a raised floor, in the ceiling, or on the wall. Cables are then run from the outlets or connecting blocks in the zone enclosure to telecommunications outlets in the work area (WA), equipment outlets serving BAS devices, or directly to BAS devices. Patch cords are used to connect voice and data equipment to telecommunications outlets and to connect BAS equipment to equipment outlets. Note that the connections in the zone enclosure are made using modular outlets and/or punch down blocks – there is no active equipment in the zone enclosure. When deploying a zone cabling solution, Siemon recommends positioning zone enclosures in the most densely populated areas of the floor space. Figure 1 shows an example of a zone cabling layout .

Figure 1: Example zone cabling layout serving voice, data, and BAS applications

Enabling flexible client work spaces that efficiently accommodate moves, adds, and changes (MACs) is a signature element of a zone cabling design. Through analyzing customers’ office reconfiguration needs, Siemon observed that zone cabling deployments have the potential to provide significant cost savings benefits compared to traditional “home run” work area to TR cabling. This is because MACs performed on traditional home run topologies require more cabling materials and more installation time to implement.

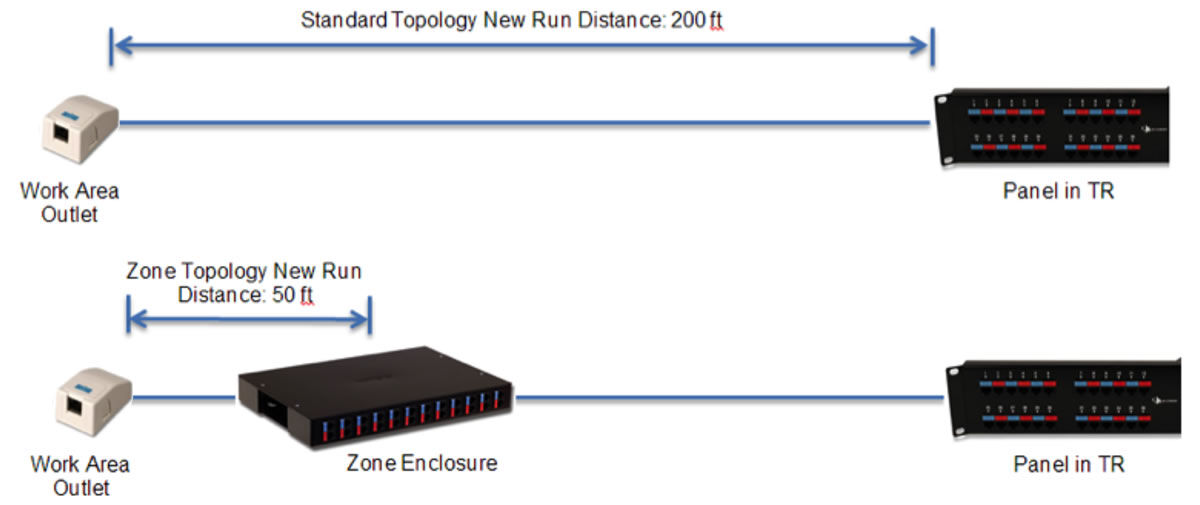

As an example, Figure 2 shows a traditional home run cabling link and a zone cabling link; both of which are supporting a work area outlet located 200 feet away from the TR. The zone enclosure is pre-cabled from the TR with spare ports available to support new services and is located 50 feet from the work area outlet. If a second cable needs to be deployed, 200 feet of new cable needs to be pulled from the TR with a traditional design, while only 50 feet needs to be pulled when using a zone design. Significantly reduced installation times and minimized client disruption are additional benefits associated with pulling 75% less cable, which all contributes to improved return-on-investment (ROI) when using zone cabling designs.

Figure 2: Example 200 foot traditional and zone cabling links depicting new cabling length required to support the addition of a new service

Zone Cabling Designs

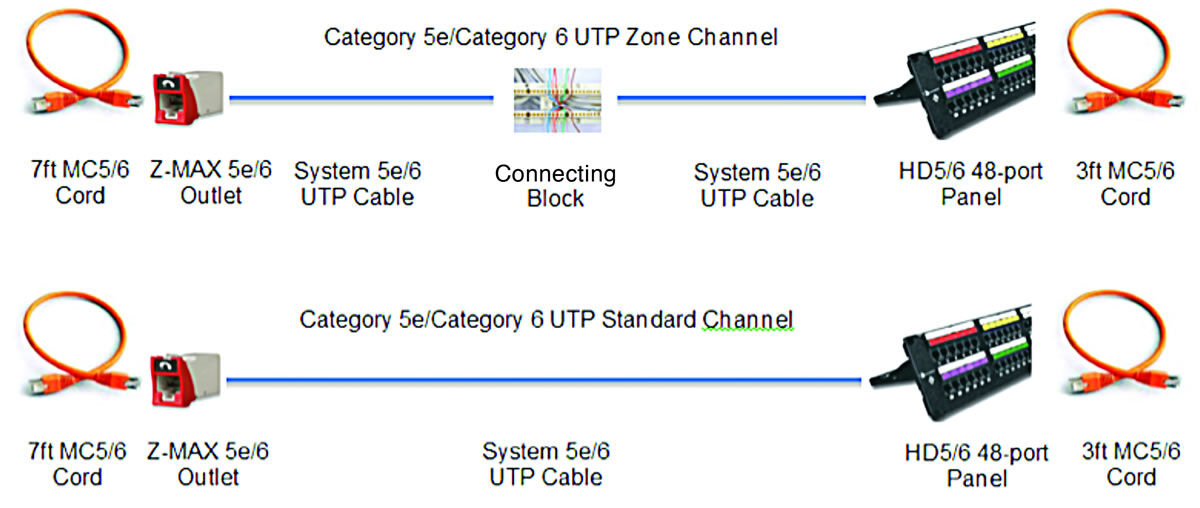

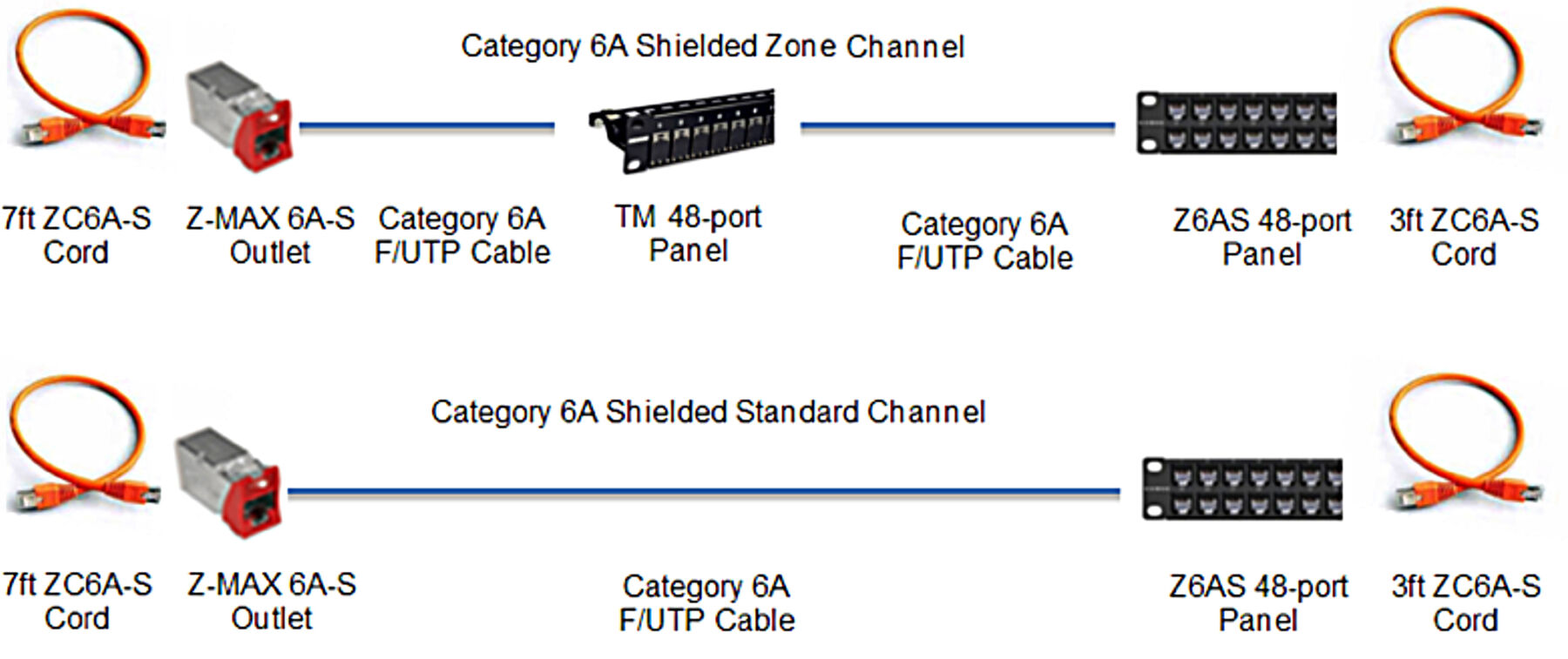

Zone cabling systems are easily implemented using a variety of Siemon components, which encompass all categories of cabling and connectivity. The diagrams in Figures 3a, 3b, and 3c depict example zone and traditional cabling channel topologies for a sampling of media types. For demonstration purposes, the connection within the zone enclosure, but not the zone enclosure itself, is shown. The components shown in these figures, with the addition of cable managers (Siemon RS3- RWM-2) and zone enclosures, formed the material list used in Siemon’s MAC cost impact study discussed later in this paper.

Figure 3a depicts Siemon’s recommended category 5e and 6 UTP zone cabling topology. Note that Siemon’s category 5e or category 6 connecting block system is the recommended connection in the zone enclosure. This solution eliminates the need to stock factory pre-terminated and tested interconnect cords for connections in the zone enclosure and simplifies cable management by eliminating cable slack. The traditional category 5e and 6 UTP cabling topology is shown for comparison purposes and for use as a reference in the cost comparison analysis.

Figure 3a: Siemon’s recommended category 5e and 6 UTP zone cabling topology and reference traditional topology

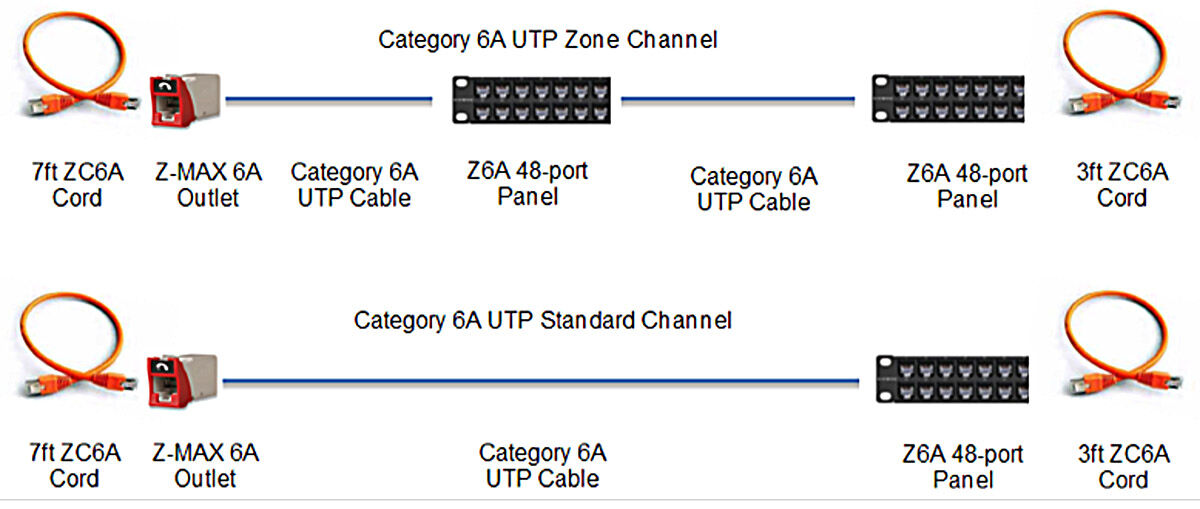

Figure 3b depicts typical category 6A UTP zone and traditional cabling topologies. These figures are provided for reference and are used in the cost comparison analysis; however, Siemon does not recommend category 6A UTP media for use in zone cabling deployments for both performance and flexibility reasons. UTP cabling may be susceptible to excessive alien crosstalk under certain installation conditions and is not the optimum media for support of remote powering applications carrying 30W and higher power loads. In addition, because category 6A UTP zone deployments rely on modular connections within the zone enclosure, factory pre-terminated and tested interconnect cords for connections must be on hand in order to quickly facilitate MAC requests. Siemon recommends cost effective shielded zone cabling solutions to overcome these concerns.

Figure 3b: Reference category 6A UTP zone cabling topology and traditional topology

Figure 3c depicts Siemon’s recommended category 6A zone topology, which is comprised of shielded cables and components. Note that Siemon’s TERA® connector is used in the zone enclosure. Because this shielded modular connector is field-terminatable, it eliminates the need to stock factory pre-terminated and tested interconnect cords and simplifies cable management by eliminating cable slack in the zone enclosure. The traditional category 6A shielded cabling topology is shown for comparison purposes and for use as a reference in the cost comparison analysis.

Figure 3c: Siemon’s recommended category 6A zone cabling topology and reference traditional topology constructed from shielded components

Quantifying the Cost Savings

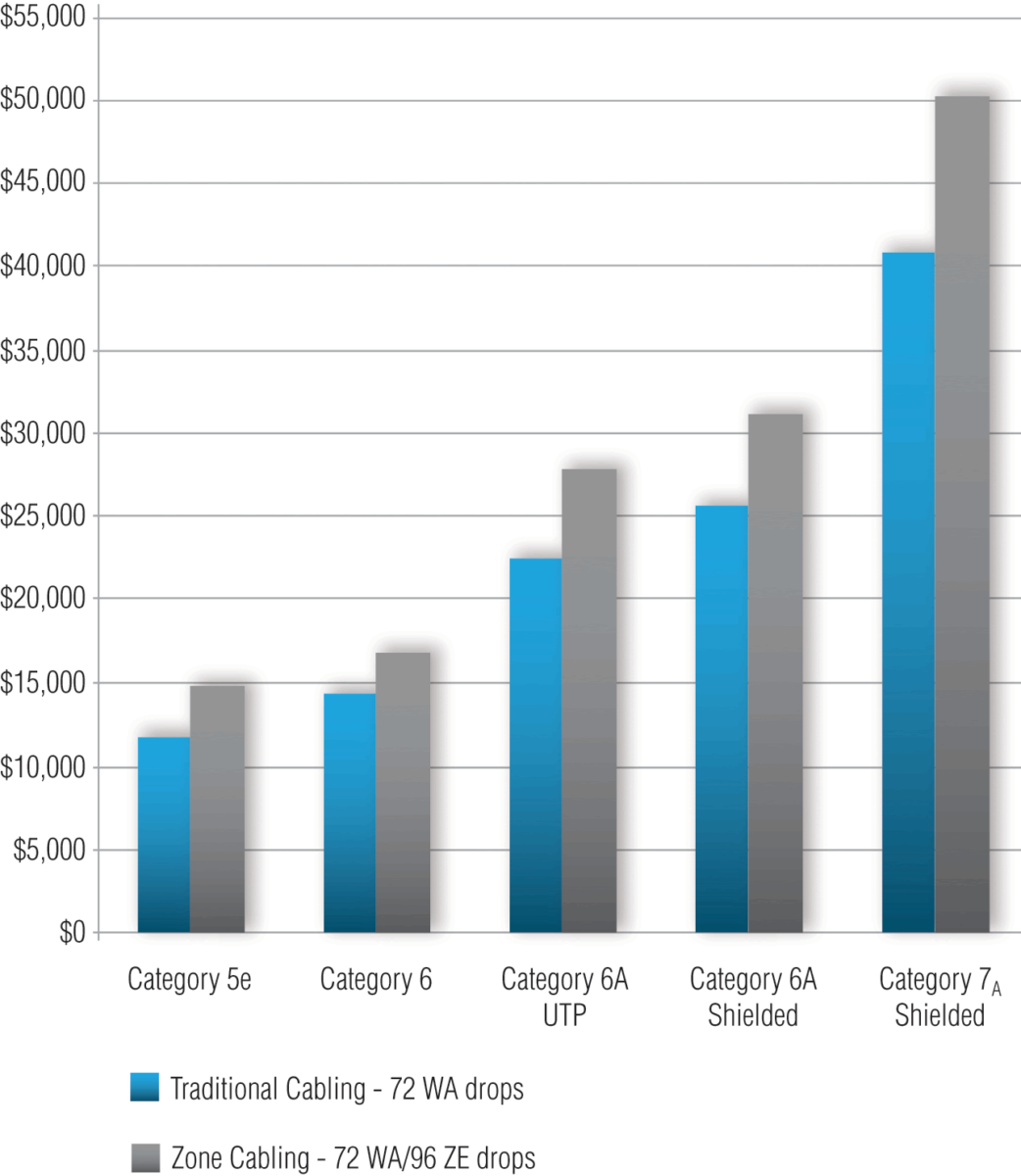

Siemon designed traditional and zone cabling layouts for a typical one-floor commercial building plenum space and analyzed the capital and operating costs associated with each design. For the purposes of this analysis, the traditional cabling topology scenario provided two outlets to 36 work areas for a total of 72 cables or “drops” and the zone topology scenario provided two outlets at 36 work areas and 72 connection points in a zone enclosure, plus an additional 24 cables pulled to the zone enclosure to accommodate future expansion.

To establish a baseline, Siemon first calculated the material and installation costs for the category 5e UTP, category 6 UTP, category 6A UTP, category 6A shielded, and category 7A shielded traditional (72 drops) and zone (96 drops to the zone enclosure and 72 drops to the work area) cabling designs and plotted the results shown in Figure 4. Media costs were derived using plenum rated materials where applicable and the labor rate was $65 (USD) per hour. Not surprisingly, the total cost for the zone cabling design is higher than for the traditional design because there is additional connectivity in each channel and some pre-cabling between the TR and zone enclosure is included for future connections. This baseline also clearly demonstrates that Siemon’s recommended shielded category 6A plenum zone cabling design provides the added benefits of performance and termination flexibility at the zone enclosure at less than 15% additional cost over a category 6A plenum UTP zone cabling design.

Figure 4: Installation and materials costs (CAPEX) for traditional and zone plenum cabling scenarios

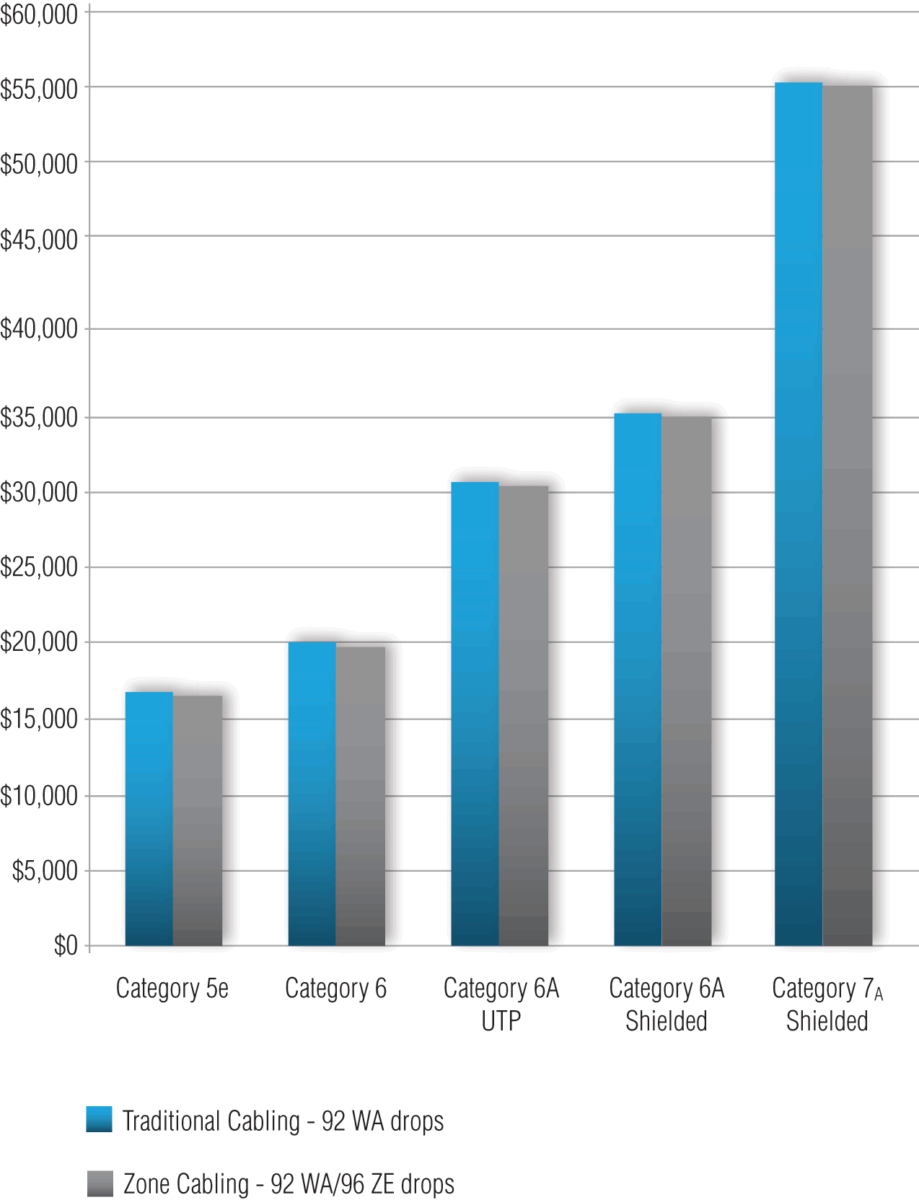

Although additional capital expenditure (“CAPEX”) is required when zone cabling is initially deployed, a more accurate assessment of the total comparative costs of these solutions must include operating expense (“OPEX”). MAC work performed on a cabling plant falls into the category of OPEX and it is in this area that the real cost benefits of a zone cabling solution become apparent. For this analysis, a cabling “add” represents the cost to pull one new cable and a cabling “move” is the cost to pull one new cable and remove the abandoned cable. The table in Figure 5 depicts Siemon’s calculated cost savings per move or add for all of the categories of cabling evaluated and the number of MACs that need to be performed for the combined CAPEX and OPEX cost associated with the traditional cabling design to equal that of the zone cabling design. This tipping point is often referred to as the time when ReturnOn-Investment (“ROI”) is achieved for a zone cabling design.

Enterprise clients’ information technology needs are dynamic and often require rapid floor space reconfiguration. Due to their enhanced ability to support MACs, building owners can realize a significant ROI benefit with their zone cabling systems within two to five years compared to traditional cabling systems. According to the cost analysis, either 10 moves and 13 adds or 12 moves and 14 adds (depending upon cabling type) will realize a full ROI of the additional CAPEX for a plenum zone cabling solution and each MAC above the ROI threshold yields additional OPEX benefits over a traditional cabling design. Depending on the number of MACs performed, a zone cabling design can pay for itself quickly.

Figure 6: Combined CAPEX and OPEX costs for traditional and zone plenum cabling scenarios after 12 moves and 14 adds

Figure 6 shows that the combined CAPEX and OPEX costs for all category plenum zone cabling designs are always lower than for traditional cabling designs after 12 moves and 14 adds are performed and there is still flexibility to add additional services to the zone cabling design!

Zone Cabling ROI

The results of this analysis may be extrapolated and applied to small, medium, and large zone cabling installations. While obviously dependent upon the exact number of moves, adds, and changes (MACs) performed per year, typical zone cabling plants of any size planned with 25% spare port availability not only significantly reduce client disruption,but allow the building owner to recoup the cost of the extra port capacity within a two to five year span or after reaching the ROI threshold (i.e. either 10 moves and 13 adds or 12 moves and 14 adds depending upon cabling type) in the example provided in this paper.

(Figure 6)

Additional Benefits

In addition to the obvious cost benefits, deployment of zone cabling provides the following additional benefits:

- Factory pre-terminated and tested trunking cables may be used for expedited installation and reduced labor cost.

- Spare ports in the zone enclosure allow for the rapid addition of new devices and facilitate moves and changes of existing services.

- Pathways are more efficiently utilized throughout the building space. • Deployment of the structured cabling system is faster and less disruptive.

- New IP devices, such as WAPs, BAS devices, voice/data security devices, audio/video devices, digital signage, etc. are easily integrated into the existing structured cabling system via connections made at the zone enclosure.

Going Green?

(Go Green Image) Zone cabling systems are ideal for use in smart and green building designs. Factory pre-terminated trunking cables can be installed for a reduction in labor costs and on-site waste and the centralized connection location within the zone enclosures allow for more efficient pathway routing throughout the building.

Integrating Siemon’s end-to-end category 7A/class FA TERA® cabling system into a zone topology allows customers to further take advantage of cable sharing strategies, which maximizes the potential to qualify for LEED credits as issued by the United States Green Building Council (USGBC). Cable sharing supports multiple low-speed, low pair count applications operating over one 4-pair cabling system, which results in more efficient cable and pathway utilization. For example, a standard IP security door deployment configuration typically consists of two category 5e cables (one for an IP camera and the other for access control) installed in a traditional home run topology. By switching to a TERA category 7A/class FA TERA cabling system configured in zone topology, a single cable can serve both devices, thereby reducing cabling and pathway materials. Although the CAPEX associated with implementing TERA category 7A/class FA TERA cabling may be slightly higher, the benefits realized by obtaining LEED accreditation can justify this additional cost.

Executive Summary:

- Today’s enterprise workspaces are increasingly more social and flexible and are subject to frequent reconfiguration and updating.

- Zone cabling enables flexible client work spaces that can accommodate moves, adds, and changes more quickly and with less disruption than traditional cabling.

- Zone cabling supports more efficient utilization of pathways and materials and is ideal for today’s smarter green building designs.

- Siemon recommends category 6A shielded cabling in zone cabling designs for maximum performance.

- Shielded category 6A plenum zone cabling designs provide the added benefits of performance, superior support of remote powering applications, and termination flexibility at the zone enclosure at less than 15% additional cost compared to category 6A plenum UTP designs.

- Zone cabling plants of any size planned with 25% spare port availability not only significantly reduce client disruption, but typically allow the building owner to recoup the cost of the extra port capacity within a two to five year span or after reaching the ROI threshold.

Rev. A 1/15